Everyone agrees the roof is important – after all, no one wants a leaky roof – but not everyone understands the options when selecting a roof system. If all of them come with a warranty, why not choose the cheapest option?

According to the 2014-2015 National Roofing Contractors Association (NRCA) Market Study, most new projects in the past few years have specified a white TPO roof. In general, TPO is a relatively low-cost, high performing, energy efficient roof membrane – when installed correctly.

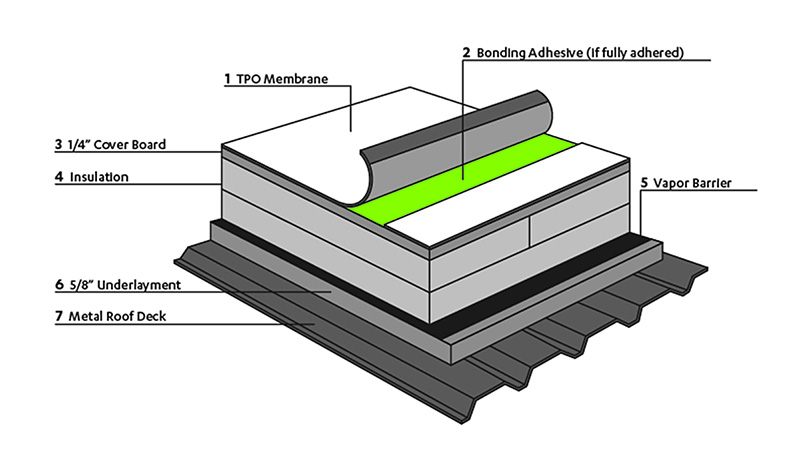

Starting with the roof membrane, we will work down through the system and discuss the pros and cons of these decisions. This information will help you make the right TPO roof selection for your next project.

01. Membrane

TPO stands for Thermoplastic Polyolefin. Thermoplastic means that it becomes plastic upon heating and hardens upon cooling and this is how it seals at the seams. A hot air welder is used to heat the membrane above and below, turning it to plastic and making it moldable. While it is still plastic, a roller is used to fuse the top and bottom membranes together, forming the watertight seam. No matter which option is chosen below the membrane, this is how all TPO roofs are sealed at the seams.

TPO is typically sold in thicknesses of 45 mil, 60 mil and 90 mil. The thicker the membrane, the better the long term durability. For example, if the owner expects workers to routinely service rooftop mechanical units, a thicker roof membrane should be considered. Warranty specifics vary based on membrane thickness and installation factors.

02. Membrane attachment

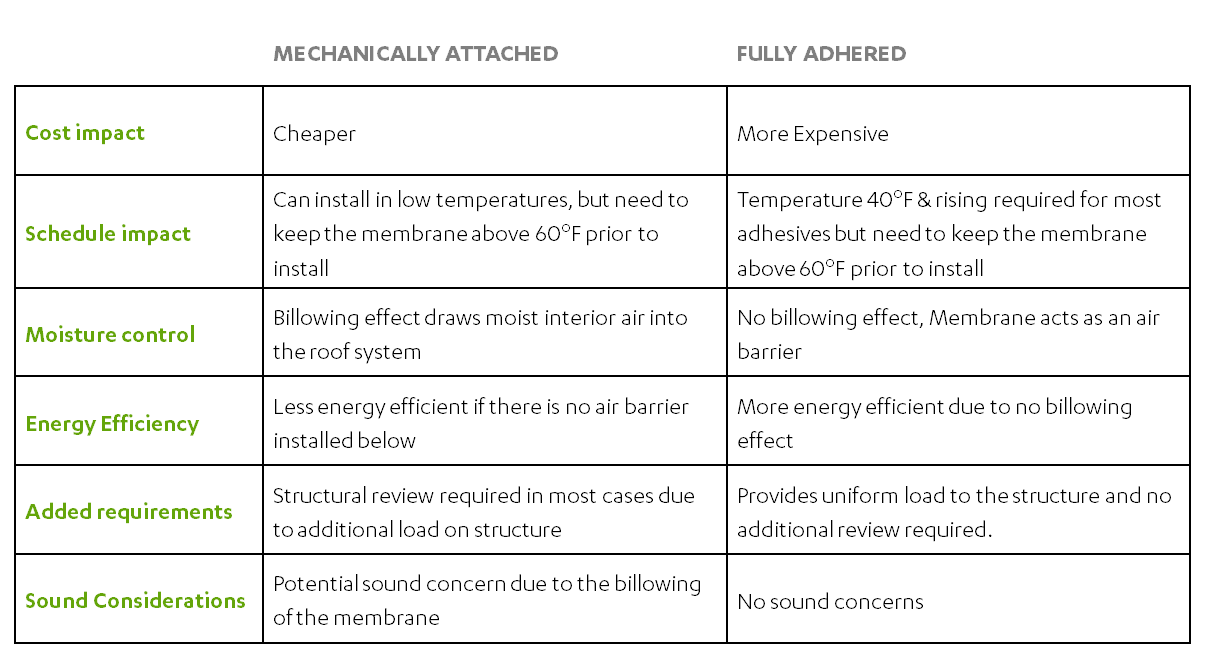

There are two primary options for attaching the TPO membrane: MECHANICALLY ATTACHED and FULLY ADHERED.

Mechanically attached

Mechanically attached membranes are fastened through the insulation boards down to the structural deck at 12″ on center (OC) in every seam on the roof. The seam is then welded outside of these fasteners.

Mechanically attached is the less expensive installation option. Its main advantage is the price. Another advantage is the ability to install in low temperatures since there is no adhesive used, however the membrane needs to be kept warm prior to installation which can be a challenge.

The downside is that mechanically attached roofs are ONLY attached in the seams – so between the seams, the membrane is loose. Strong winds creating negative uplift and positive building pressure can cause the membrane to billow up.

IF your building is located in a HVWZ (High-Velocity Wind Zone) prone to hurricanes. etc., this method is not recommended for obvious reasons.

Fully adhered

Fully adhered TPO roof systems are adhesive bonded to the substrate using a contact adhesive applied to both the membrane and the substrate. Typically, this is a water based adhesive which could lose it’s bonding capability if it becomes wet and this consideration should be a primary concern if your building is in a HVWZ and prone to flying debris which could puncture the membrane during a hurricane. The substrate under the membrane is either a cover board or the top layer of insulation. Fully adhered systems cost a premium and offer several advantages over their mechanically attached counterparts.

Since the system is fully adhesive bonded to the substrate, this eliminates issues with billowing, makes it less prone to condensation under the membrane and makes it more energy efficient. A fully adhered membrane is considered an air barrier, which is required on the roof per 2012 IECC. The fully adhered membrane provides uniform loading of the structure during extreme negative uplift in a high-velocity wind condition.

Given the performance advantages of a FULLY ADHERED TPO roof system, it is the preferred installation option for most commercial construction projects.

It should be noted that ALL roof system warranties are VOID in a named storm in excess of 110mph except the Spray Polyurethane Foam (SPF) Roof System which carries a Category5 Hurricane Wind Warranty.

CALL US TO DISCUSS THE BEST ROOF SYSTEM OPTION FOR YOUR SPECIFIC BUILDING NEEDS.